- 1

- 2

|

Details

Position:

Home>

Details

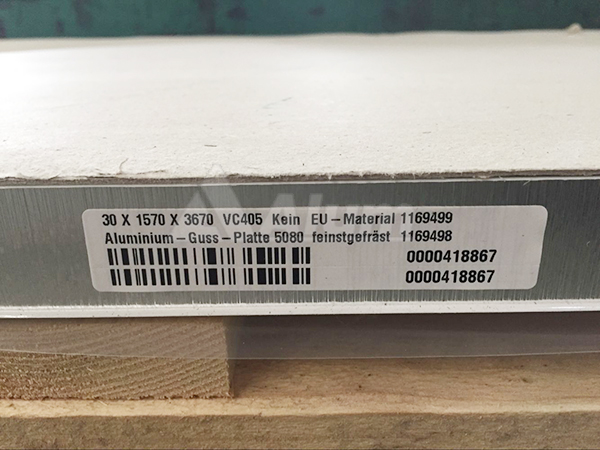

ACP5080

alloy composition EN AW-5083 (AlMg4.5Mn0.7), Standard: DIN EN 573-3 / 3.3547 Place of Origin: Germany Material attributes Machining performance is very good (HSC/HPS is excellent) Good welding performance (TIG, MIG) (using S Al 5183) Good anodizing performance, no masking modification Polishability is very good Corrosion resistance is very good EDM workability is good Typical mechanical characteristics Tensile strength R m 240-290 MPa (N/mm 2) 0.2% yield strength R p 0.2 110-130 MPa (N/mm 2) Elongation at break A 5% 15 Brinell hardness HB 70 Typical physical properties Density 2.66 g/cm 3 Thermal conductivity 110-140 W/(mK) Conductivity 16-19 MS/m (m/Ω mm 2) Elastic modulus ~70,000 N/mm 2 Coefficient of thermal expansion 24.2 * 10 -6 /K Thickness and size Supply ruler for cast aluminum standard plates and custom cut pieces with a thickness of 5 mm to 100 mm The inch range is: Thickness* Maximum width* Maximum length* ≥ 5 mm x 1320 mm x 3020 mm (up to 6000 mm) ≥ 5 mm x 1520 mm x 3020 mm (up to 6000 mm) ≥ 10 mm x 1570 mm x 3670 mm (up to 6000 mm) ≥ 15 mm x 2160 mm x 4000 mm (up to 6000 mm) (The wafer, ring and special shape cut pieces can be customized as required.) Width greater than 2160 mm: Please refer to the product information about ACP 5080 GIANT / ACP 5080R GIANT tolerance Surface roughness R a ≤ 0.3 μm Thickness tolerance +/- 0.1 mm Flatness thickness 6-12 mm ≤ 0.40 mm** Thickness> 12-100 mm ≤ 0.13 mm** Cast plate width tolerance 0/+10 mm Cast plate length tolerance 0/+15 mm Custom cut tolerance (length/width) DIN ISO 2768-m (Stricter control can be carried out as needed) *Other sizes can be customized on demand. The company reserves the right to change the technical content. ** Measured in a straight line per meter |